Transform Your Surfaces with a Long-Lasting, Crystal-Clear Finish

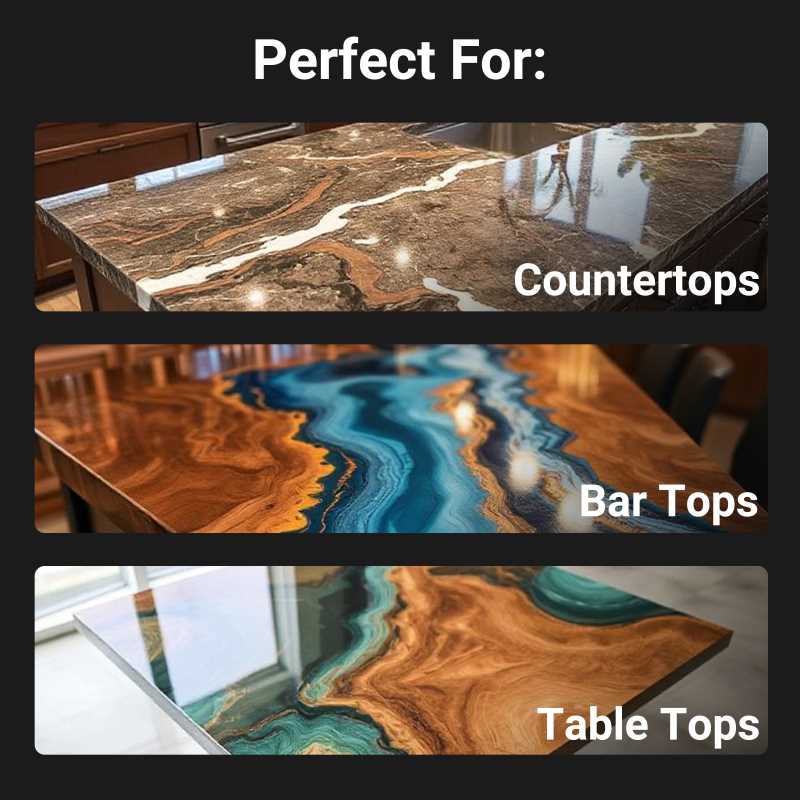

Pourla Countertop Epoxy Resin is engineered for durability, heat resistance, and a stunning high-gloss look. Designed for epoxy countertops, bar tops, table tops, coasters, and other surfaces, providing a professional-quality finish.

PERFECT EPOXY FOR countertops, bar tops, table tops, and coasters

Pourla Countertop Epoxy is designed for surfaces that need a tough, heat-resistant finish. It works great for countertops, bar tops, table tops, and coasters, offering long-lasting durability. Whether you are DIYing kitchen counter, dining table, or coffee table, our countertop epoxy stands up to daily use, making it a reliable choice for high-traffic areas. It's not just for homes—its strength and resilience also make it ideal for bars, restaurants, and workspaces where surfaces see heavy wear.

This epoxy bonds well to wood, marble, tile, laminate, granite, and concrete, creating a smooth, seamless coat. Thanks to its self-leveling formula, it spreads evenly for a glossy, glass-like finish without bubbles or streaks. Whether you're refinishing an old surface or working on a brand-new project, this resin helps you achieve a professional, polished look with minimal effort and less cost.

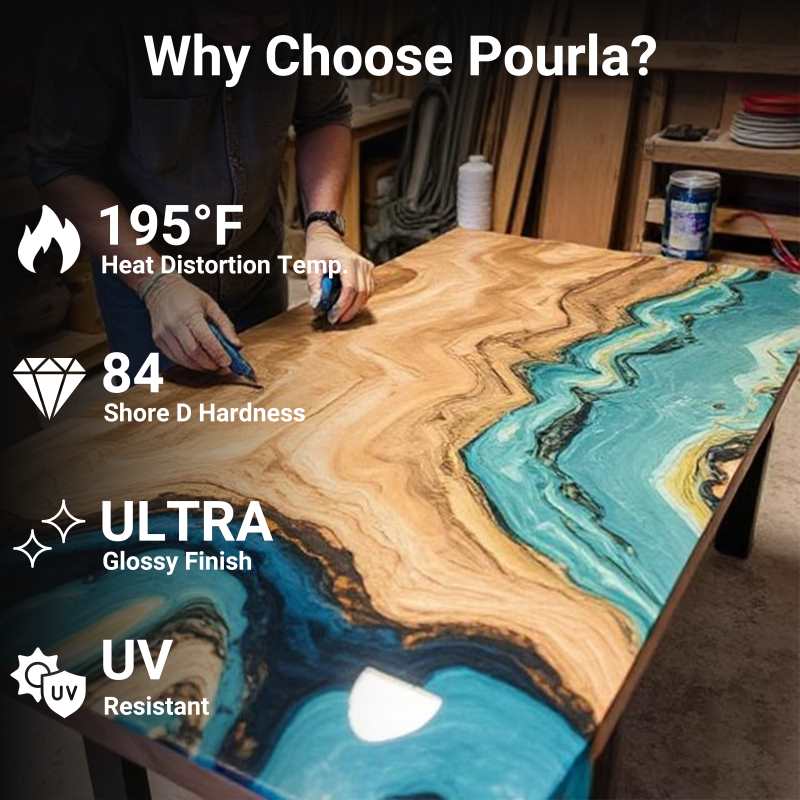

Why Choose Pourla Countertop Epoxy?

The benefits speak for themselves:

Heat Distortion Temperature of 195°F(90°C)

Withstands everyday heat exposure from warm plates, coffee mugs, and indirect heat.

Crystal-Clear, Ultra-Gloss Finish

Cures to a glass-like, high-gloss surface that enhances the natural beauty of your countertops.

Easy 1:1 Mixing – No Experience Needed

Simple 1:1 mixing ratio by volumn for an effortless application.

Built for Durability

Scratch-resistant, stain-resistant, and impact-resistant to handle daily wear and tear.

Advanced Heat Resistance For Your Epoxy Countertops & Real HDT (90°C / 195°F)

Unlike other epoxy brands that claim about heat resistance(may up to 500°F) and unclearing about the HDT, Pourla Countertop Epoxy has lab-tested HDT of 195°F / 90°C, ensuring durability against hot cookware and daily use.

In addition, it is essential to understand the difference between heat resistance and heat distortion temperature (HDT) to set the right expectations for your projects with the right resin.

Heat Resistance vs. HDT: What’s the Difference?

- Heat Resistance Temperature: This is the absolute threshold where a cured epoxy surface begins to break down or melt. Once epoxy reaches this temperature, the damage is permanent and irreversible—it can discolor, warp, or even develop burn marks. No amount of cooling or repairs can restore it to its original state.

- Heat Distortion Temperature (HDT): HDT refers to the temperature at which the cured epoxy begins to soften, but it does not permanently deform. When the temperature drops below the HDT, the surface hardens again without lasting damage.

How This Applies to Pourla Countertop Epoxy

Pourla Countertop Epoxy Resin has an HDT of 90°C (195°F), meaning it can handle everyday heat exposure such as warm plates, coffee mugs, and indirect heat without losing its clarity or durability. However, placing hot cookware, baking trays, or pans directly on the surface above this temperature can cause irreversible damage. To keep your countertops, bar tops, and tables looking their best, always use trivets or heat pads when dealing with extreme heat.

By understanding the difference between HDT and heat resistance, you can ensure your epoxy-coated surfaces remain beautiful, durable, and protected for years to come.

High UV Stability Prevents Yellowing Overtime

Over time, exposure to sunlight and indoor lighting can cause epoxy surfaces to yellow, fade, or lose their original brilliance. Pourla Countertop Epoxy Resin is formulated with advanced UV stabilizers, protecting your surfaces from premature discoloration and ensuring a crystal-clear, high-gloss finish that lasts. Whether used in residential kitchens or high-traffic commercial spaces, our epoxy resists yellowing far better than standard formulas, keeping countertops, bar tops, and tables looking pristine for years to come.

With Pourla Countertop Epoxy Resin, you’re investing in more than just durability—you’re setting yourself apart with premium, professional-grade results. Our high-performance, self-leveling formula delivers a flawless finish that enhances any space, helping you increase customer satisfaction, reduce costly touch-ups, and build a reputation for quality. Perfect for both DIYers and professionals, it’s the go-to choice for stunning, long-lasting surfaces that stand the test of time.

Extreme Durability with 84 Shore D Hardness

Strength and resilience matter when it comes to epoxy surfaces, and Pourla Countertop Epoxy Resin delivers exceptional durability with a Shore D hardness rating of 84. This high level of hardness ensures that your countertops, bar tops, and table tops can withstand daily wear and tear, heavy use, and impact without compromising their flawless finish. Whether in a busy home kitchen or a high-traffic commercial setting, Pourla provides a tough, scratch-resistant surface that maintains its beauty over time.

SPECIFICATIONS

Technical Specifications

- Color: Epoxy Resin(Clear) Epoxy Hardener(Clear)

- Density: Epoxy Resin(70 ± 2 lb/ft³) Epoxy Hardener(60 ± 1.9 lb/ft³)

- Resin Viscosity: 7500 - 9500 cP @ 75°F

- Hardener Viscosity: 800 - 1600cP @ 75°F

- Mix Ratio by Volume: 1A:1B (1 part resin to 1 part hardener)

- Mix Ratio by Weight: 1.2A:1B

- Recommended Working Temperature: 50-158°F

- Maximum Working Time: 30 minutes (at 75°F)

- Final Cure Time:36-48 hours (at 75°F)

- Initial Cure Time: 5-6 hours (at 75°F)

- Applicable Materials: wood, marble, tile, laminate, granite, and concrete

Work Environment

- Keep the adhesive containers clean. Mix components A and B strictly according to the specified ratio. Accurately measure the components, stir thoroughly along the inner wall of the container in a clockwise direction until evenly mixed, and let the mixture sit for 3-5 minutes before use.

Precautions

- Adjust the amount of adhesive mixed according to the operational time and required usage to avoid waste. When the temperature is below 60°F, preheat component A to 86°F before mixing to ensure easier handling (as component A thickens in lower temperatures). After use, seal the container lid tightly to prevent moisture absorption, which could render the product unusable. When the relative humidity exceeds 85%, the cured material surface may absorb moisture from the air, forming a white fog-like layer.

Testing Data

The typical data was measured in a laboratory environment with a temperature of 77°F and a humidity of 70%.

- Hardness: Shore D 80-84

- Heat Distortion Temperature:195°F

- Water Absorption Rate: <0.1%

Frequently Asked Questions

Yes! Pourla Countertop Epoxy Resin is compatible with pigments, dyes, metallic powders, and other decorative elements. This allows you to create custom colors and artistic designs for your surfaces.

If your Epoxy Resin is not curing properly, there are several possible reasons for this:

Incorrect Mixing Ratio: Epoxy resin requires an exact 1:1 ratio by volumn of resin and hardener. If the ratio is off, the resin may not cure properly. Make sure to mix equal parts thoroughly to ensure a proper cure.

Insufficient Mixing: If the resin and hardener are not mixed thoroughly, it can result in incomplete or uneven curing. Be sure to mix for at least 3-5 minutes, scraping the sides and bottom of the mixing container to ensure everything is fully blended.

Temperature Issues: Epoxy needs the right temperature to cure effectively. Cold temperatures (below 60°F/15°C) can slow down the curing process, while high temperatures can cause it to cure too quickly and unevenly. Make sure your workspace is within the recommended temperature range of 70°F-80°F (21°C-27°C).

Humidity Levels: High humidity can interfere with the curing process, leading to sticky surfaces or improper hardening. Try to work in a space with humidity levels below 70% for the best results.

Expired or Contaminated Resin or Hardener: If the resin or hardener is old or has been stored improperly, it may not cure correctly.

If you've checked all of these factors and your resin is still not curing, contact us directly for a solution

Reviews

Clear filtersThere are no reviews yet.