Unmatched Heat Resistance – A Game-Changer for Your Projects

POURLA 1:1 Ultra Heat Resistant Epoxy Resin stands as the perfect solution because it is 3X more heat resistant at 195°F while other epoxies reach only 110°F. Flawless crafts like trays, coasters, and carbon fiber parts become effortlessly easy.

Ultra Heat Tolerance

If you are a craft lover, an artist, or a professional maker, you understand the issue with regular resins that they don't have high temperature tolerance. Traditional epoxies can warp, discolor, or lose their structural elements if they are used at high temperatures.

In every project, whether you are creating a fiber part or resin coaster or putting on a final touch with a heat impact resistant coat, you'll need a resin that not only has beautiful finish but also does not compromise on quality.

Key Features

The benefits speak for themselves:

Heat Distortion Temperature

195°F

Shore D

Hardness

80-84

Water

Absorption

<0.1%

Cure

Time

36-48 hours

Why You Need Heat Resistance Resin in Your Projects

Every project requires durable outcomes with long-lasting results particularly when heat is an operating factor. Here is how The Ultra Heat Resistant Epoxy Resin from POURLA can give you better performance than typical resin products

Standard Resins

Most regular resins experience warping, cracking and discoloration when they encounter the heat generated by everyday items like coffee mugs, hot pans and outdoor elements. Standard resins can ruin your projects when dealing with heat that can not be used long term.

Ultra Heat Resistant Epoxy Resin

POURLA resin boasts superior durability with a Heat Distortion Temperature of 195°F, meaning your projects remain intact, strong and flawless. Whether you’re making heat-resistant coasters, carbon fiber parts or applying protective coatings, your work will retain its quality under heat.

The Ideal Resin for DIYers, Crafters, and Professionals

If you are a Crafters, DIY enthusiast, hobbyist, or professional in resin art and want to advance your DIY crafts, you need an ideal resin like POURLA’s Epoxy Resin which features ultra heat resistance. You will also love easy-to-use properties of this epoxy.

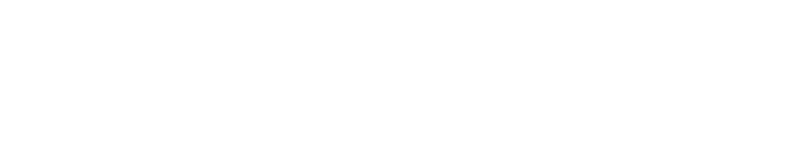

It can be used to:

- Creating coasters and trays that stay strong and beautiful even when exposed to high temperatures.

- Making carbon fiber parts that require durability and heat resistance.

- Topcoating surfaces to add a protective, heat-resistant layer that won't warp under stress.

Why Choose POURLA’s Ultra Heat Resistant Epoxy Resin?

POURLA 1:1 Ultra Heat Resistant Epoxy Resin has this ability and can offer superior performance which is ideal to use for DIY crafters and professionals.

Here is why:

- Exceptional Heat Resistance

Resists heat up to 195°F, much higher than standard resins, ensuring your projects stay intact, even under high temperatures. - Easy to Use and Versatile

The 1:1 mix ratio makes this product easy to use for wood, marble and concrete applications suitable for home projects and industrial requirements. - Durability and Long-Lasting Strength

It reaches Shore D hardness levels of 80-84 and it keeps its shape thanks to its low water absorption while fighting off typical wear and tear. - Quick Curing Time

Sets in 5-6 hours, with a full cure time of 36-48 hours, providing quick turnaround without sacrificing quality.

How to Use POURLA Ultra Heat Resistant Epoxy Resin

To achieve flawless results, follow these simple steps:

- Prepare the Workspace

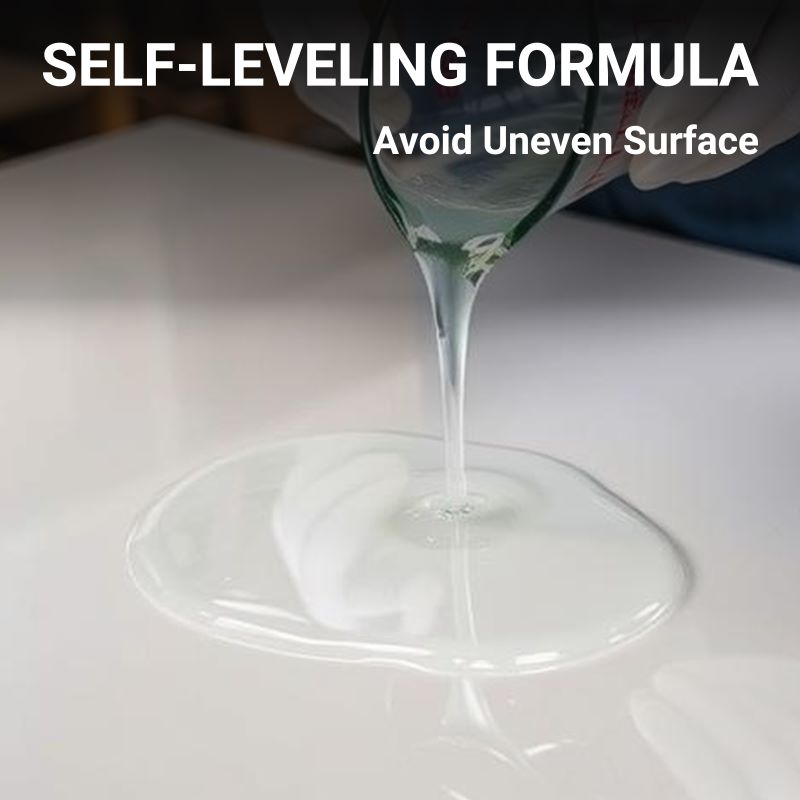

A workspace temperature between 50-158°F ensures best results when working with POURLA Ultra Heat Resistant Epoxy Resin. - Mix the Components

Combine the mix by using one part resin with one part hardener at volume ratio (or 1.2A:1B by weight measurements). Thoroughly mix the components by stirring for 3 to 5 minutes until they reach a complete combination. - Apply the Resin

Pour the mixture onto your project surface during the 25-30 minute working time period. - Allow to Cure

Let the resin cure for 36-48 hours at room temperature. The resin will begin setting within 5-6 hours. - Finishing Touches

Once fully cured, your project will have a smooth, durable, heat-resistant finish.

With these steps, your project will be finished with the perfect heat-resistant finish, ensuring long-lasting quality and durability.

SPECIFICATIONS

Technical Specifications

- Color: Epoxy Resin(Clear) Epoxy Hardener(Clear)

- Density: Epoxy Resin(70 ± 2 lb/ft³) Epoxy Hardener(60 ± 1.9 lb/ft³)

- Mix Ratio by Volume: 1A:1B (1 part resin to 1 part hardener)

- Mix Ratio by Weight: 1.2A:1B

- Recommended Working Temperature: 50-158°F

- Maximum Working Time: 30 minutes (at 75°F)

- Final Cure Time:36-48 hours (at 75°F)

- Initial Cure Time: 5-6 hours (at 75°F)

- Applicable Materials: wood, marble, tile, laminate, granite, and concrete

Work Environment

- Keep the adhesive containers clean. Mix components A and B strictly according to the specified ratio. Accurately measure the components, stir thoroughly along the inner wall of the container in a clockwise direction until evenly mixed, and let the mixture sit for 3-5 minutes before use.

Precautions

- Adjust the amount of adhesive mixed according to the operational time and required usage to avoid waste. When the temperature is below 60°F, preheat component A to 86°F before mixing to ensure easier handling (as component A thickens in lower temperatures). After use, seal the container lid tightly to prevent moisture absorption, which could render the product unusable. When the relative humidity exceeds 85%, the cured material surface may absorb moisture from the air, forming a white fog-like layer.

Testing Data

The typical data was measured in a laboratory environment with a temperature of 77°F and a humidity of 70%.

- Hardness: Shore D 80-84

- Heat Distortion Temperature:195°F

- Water Absorption Rate: <0.1%

Frequently Asked Questions

HDT stands for heat distortion temperature. It measures the temperature at which a cured material begins to soften and deform under a specific load. In simple terms, HDT indicates how well an epoxy maintains its shape and performance when exposed to heat.

Pourla ultra heat resistance resin has HDT of 195°F. This makes it well suited for projects that require higher heat resistance compared to standard epoxy systems.

No. While a higher HDT means better resistance to heat-related deformation, no epoxy is completely heat-proof. We recommend using protective pads or insulation when exposing finished pieces to high temperatures for extended periods.

Yes. As a result of this resin’s ability to withstand extreme weather, it can be used both indoor and outdoor.

This material is set in two stages. The first stage is completed within 5-6 hours while full cure is achieved in between 36-48 hours at room temperature.

This epoxy is ideal for coasters, trays, carbon fiber parts, and other applications where elevated heat resistance is important. It’s commonly used in functional items that may be exposed to warm or hot objects during normal use.

Because this epoxy has a higher viscosity, we recommend mixing thoroughly for 5–7 minutes. Proper mixing ensures consistent curing, heat resistance, and overall performance.

Reviews

Clear filtersThere are no reviews yet.