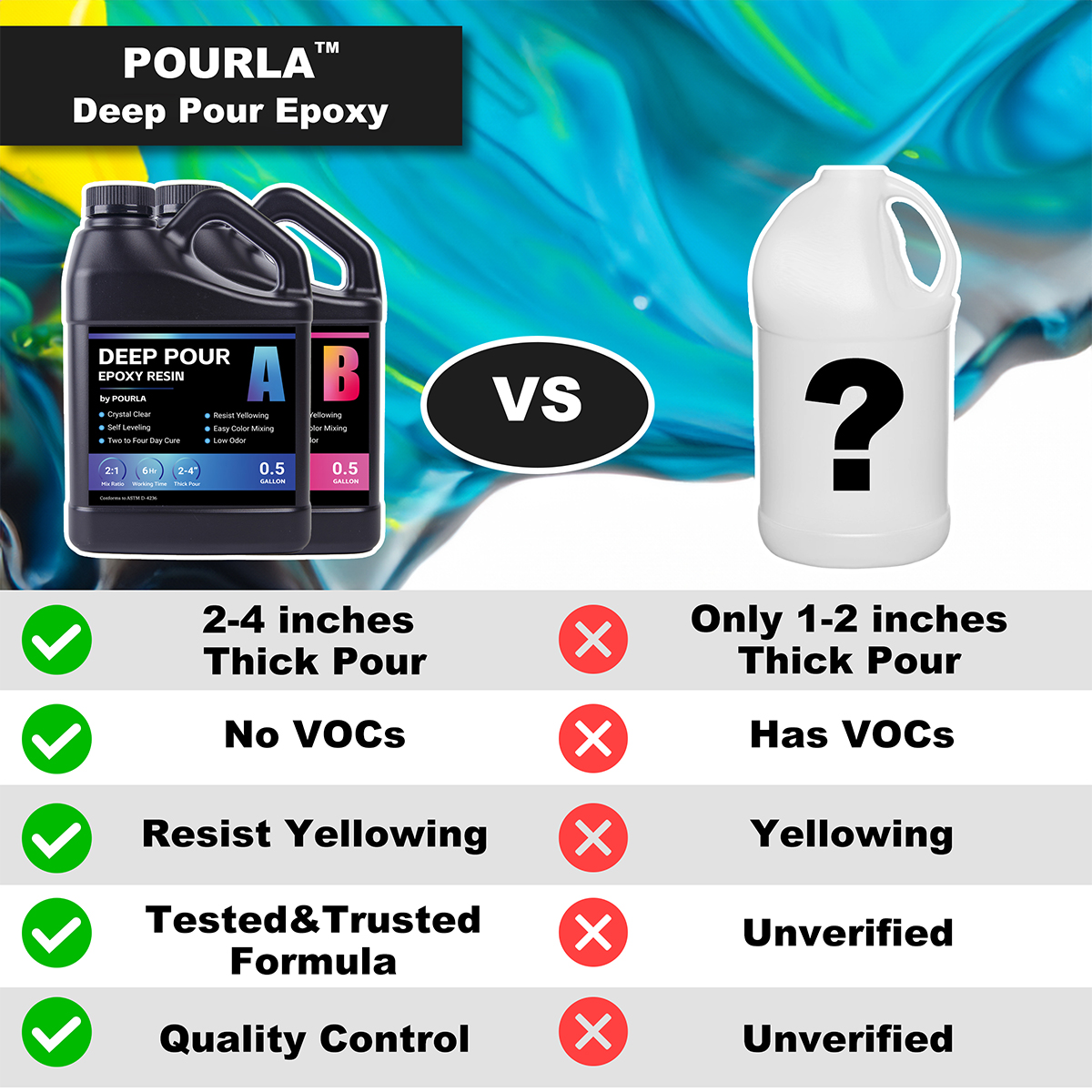

Designed and formulated for artists and makers

Pourla deep pour epoxy resin is a versatile and durable material widely used across various industries and applications. It can be used to protect tabletops and floors, making jewelry and river tables, used as paint or glue.

High Viscosity and Slow Curing

Our deep pour resin is formulated to handle the heat from thicker pours. At 75F, it will start to cure in 36-48 hours, completely cure in 100 hours, resulting in a durable, clear, high-gloss finish.

River Tables

Our deep pour epoxy resin kit is perfectly designed for your epoxy river table projects. It is designed to be easily flowing and slowly curing, making it easy to fill any cracks in your wood.

Art Works

Mixing our epoxy resin and color pigments is totally easy thanks to our low-viscosity formula.

Casting

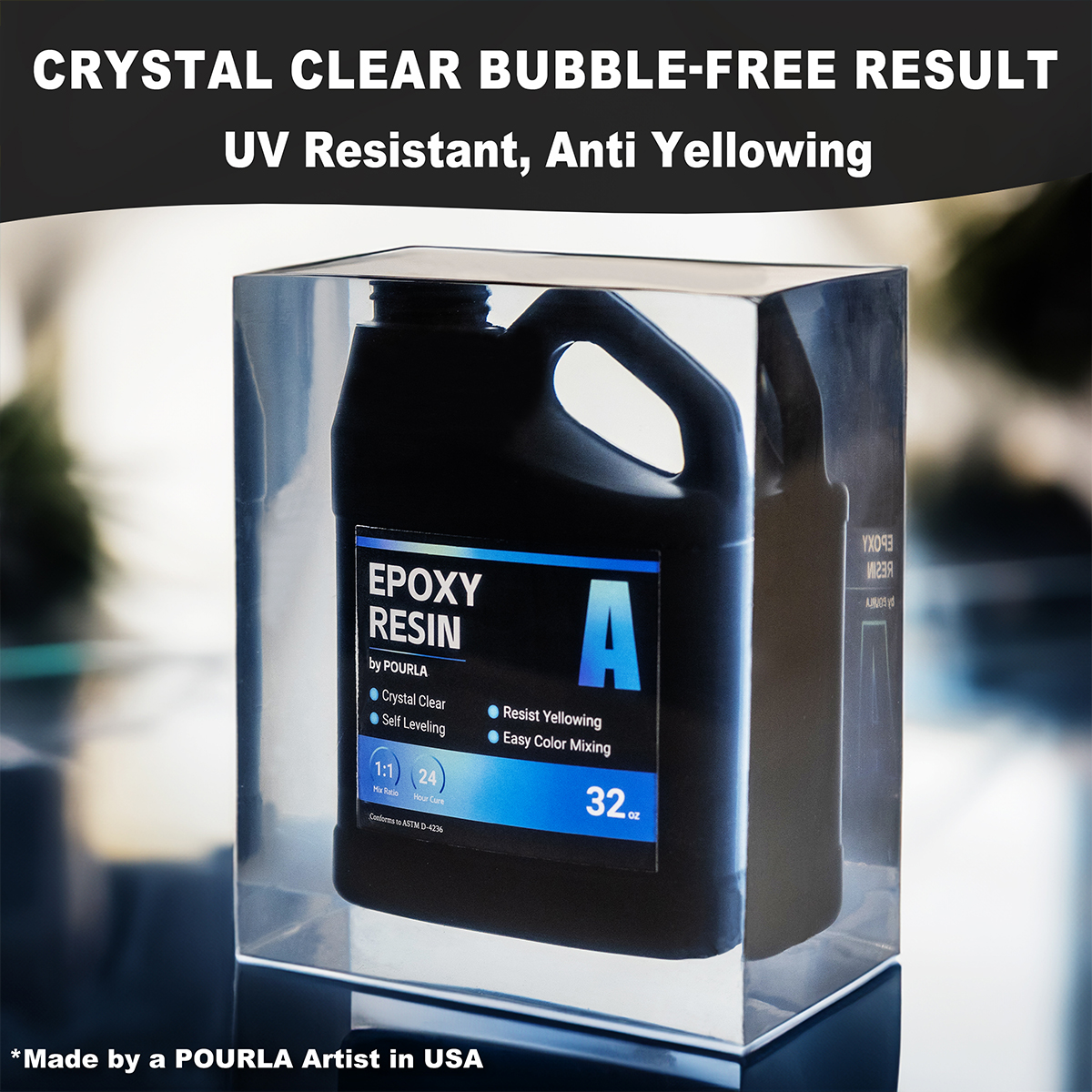

Our resin is also perfect for your casting projects since we designed it to have crystal clear finish and anti-yellowing formula.

Other Crafts

You can use our deep pour epoxy resin in any projects that need thicker pours of resin. And you will have more time to work on it than regular epoxy resin.

See How Well It Performs in Real Projects

SPECIFICATIONS

Technical Specifications

- Color: Epoxy Resin(Clear) Epoxy Hardener(Clear)

- Density: Epoxy Resin(1.05±0.03 g/m3) Epoxy Hardener(0.98±0.02 g/m3)

- Pour Depth: up to 4 inches in single pour

- Mix Ratio by Volume: 2A:1B (2 part resin to 1 part hardener)

- Recommended Working Temperature: 50-158°F

- Maximum Working Time: 6 hours (at 75F)

- Cure Time: 70-100 hours (at 75F, depending on actual pour thickness)

- Substrates: Carbon Fiber, Fiberglass, Epoxy, Wood, Prepared Metals, Masonry, Concrete, Glass, Stone

Work Environment

- Keep the adhesive containers clean. Mix components A and B strictly according to the specified ratio. Accurately measure the components, stir thoroughly along the inner wall of the container in a clockwise direction until evenly mixed, and let the mixture sit for 3-5 minutes before use.

Precautions

- Adjust the amount of adhesive mixed according to the operational time and required usage to avoid waste. When the temperature is below 15°C, preheat component A to 30°C before mixing to ensure easier handling (as component A thickens in lower temperatures). After use, seal the container lid tightly to prevent moisture absorption, which could render the product unusable. When the relative humidity exceeds 85%, the cured material surface may absorb moisture from the air, forming a white fog-like layer.

Testing Data

The typical data was measured in a laboratory environment with a temperature of 25°C and a humidity of 70%.

- Hardness: Shore D 81-83

- Flexural Strength: 28 Kg/mm²

- Heat Distortion Temperature: 50°C

- Water Absorption Rate: <0.1%

- Compressive Strength: 8.4 Kg/mm²

Reviews

There are no reviews yet.